Turbine tsayayye ruwa diaphragm

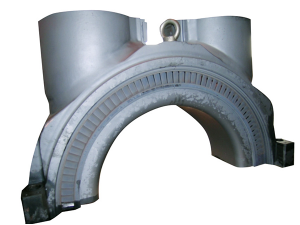

A lokacin aikin kera diaphragm, babbar matsalar ita ce haɗin kai tsakanin igiya mai tsayi da jikin diaphragm da zobe na waje.Abubuwan buƙatun fasaha duk an gabatar da su ga wannan matsalar.Haɗin da ke tsakanin tsayayyen ruwa da jikin diaphragm da zobe na waje dole ne ya sami isasshen ƙarfi, sashin tururi na diaphragm dole ne ya sami madaidaiciyar sifar giciye da yanki, da'irar farar ya kamata ta kasance mai ma'ana tare da cibiyar diaphragm, mashigai da gefuna na kanti. ruwan da ke tsaye ya kamata ya kasance a cikin jirgin sama ɗaya, kuma diaphragm ɗin da aka sarrafa ya kamata ya sami isasshen santsi, Don tabbatar da ƙarancin iska.Jirgin saman gefen fitowar tururi na waje na zoben diaphragm yana layi daya da jirgin saman gefen wurin tururi na tsayayyen ruwa don tabbatar da haɗin gwiwa tare da Silinda.

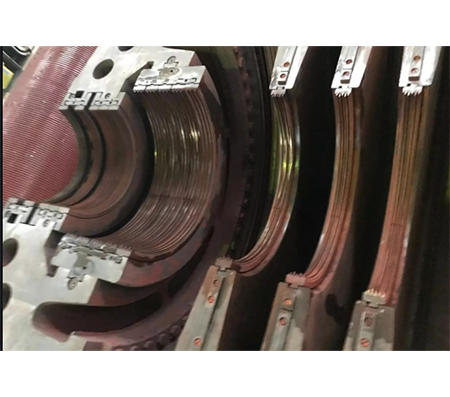

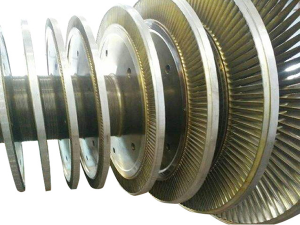

Manufar turbine diaphragm: ana amfani dashi don gyara tsayayyen ruwan wukake da samar da bangon bangare a duk matakan injin tururi.Yawanci ya ƙunshi jikin diaphragm, tsayayyen ruwan wukake da gefen waje na diaphragm.Ana shigar da diaphragm na turbine a cikin tsagi na diaphragm akan bangon ciki na silinda ko sanya shi akan silinda ta hannun hannun diaphragm.Kamar yadda aka nuna a kasa:

Akwai ma'aikatan sarrafa fasaha sama da 20 a cikin taron bitar na kamfaninmu.Wadannan ma'aikata sun tsunduma a cikin ƙwararrun masana'antu da sarrafa ɓangarorin fiye da shekaru goma, kuma suna sanye take da kayan aikin gwaji na ƙwararru: na'urori masu karantawa kai tsaye, masu gano flaw ultrasonic, micrometers na ciki da na waje na musamman, da sauransu don tabbatar da ingancin inganci. da ikon samar da mai rarrabawa da kuma saduwa da bukatun abokan ciniki, kamfanin yana da nau'i-nau'i na tsaye daban-daban, na'ura mai kariya na gas ta atomatik da kuma manyan kayan sarrafawa na lambobi, kamar 1.6m, 2.5m da 4m.